How was asbestos mined and made into usable fibers? I honestly did not know that asbestos was mined (I was led to believe it was man made) until I started doing research into the subject. What I have found in sources from over 100 years ago is that they thought the world of asbestos and they saw it bettering the lives of people and not as something that would cause cancer and destroy families.

Interesting Facts About Asbestos

One of The Most Wonderfull Substances Dug Out of The Earth

Asbestos, one of the most wonderful substances dug out of the earth, has been much in the public eye since the Iroquois theatre disaster. Now, it is reported, the bulk of the world’s supply for many years to come has been secured by the Standard Oil interests, for the purpose of making fire proof “timber” and tunnel sheathing.

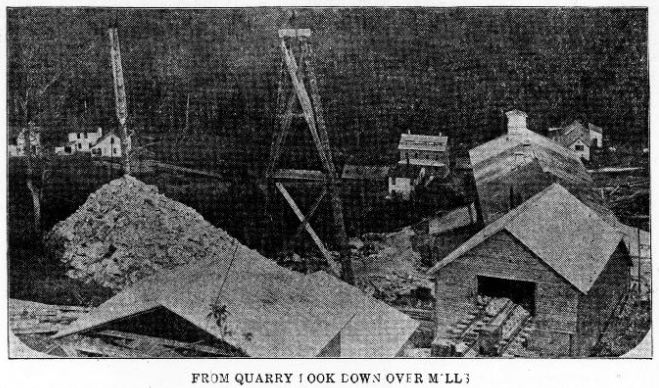

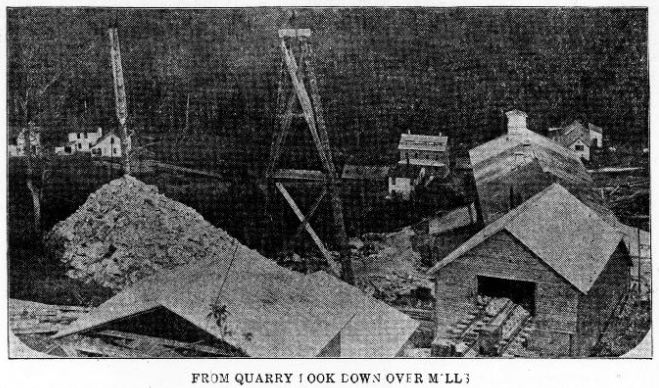

The supply of asbestos is limited. Most of it comes from Canada, and it is found in Oregon, Idaho, California and other western states. It also is mined in the Italian Alps, whence most of the supply came before it was discovered in Canada. But except in the latter country, the veins of the greasy feeling silky like fibrous stuff are too thin to be worked with profit, for the problem of mining asbestos is found in the disposition of the foreign matter in which the asbestos is entombed. In the Canadian mines only about 4 percent of the material quarried is asbestos; the rest is made up of rock and other refuse.

Asbestos occurs in veins varying from half an inch to four inches thick between layers of hornblende crystals. The longer, tougher fibers are found in the deepest diggings. The less valuable asbestos — that is, the short, easily pulverized fibers — are found near the surface. The mining is much like rock quarrying. Holes are drilled and dynamite exploded to blast out a layer, which falls to the floor of the working. The workmen break out as much of the pure asbestos in as large lumps as possible, load the lumps into tubs or skips, and send it to the surface, where boys and young men “cob” or crumble the rock away from the asbestos.

The lumps of asbestos are packed in rough bales and shipped to this country to be manufactured into the finished product. The asbestos as it comes from the mine is of a yellowish or greenish color, the edges furred with loose fiber. The best grades of asbestos are white, and the fine fiber is long enough to be carded and spun into yarn and then woven into a greasy feeling, dirty white cloth which is fire proof, acid proof, and weather proof.

When the lumps of raw asbestos reach the factory they are placed in machines which crush them until the fibers are loosened into fluffy, cottony masses. From the crushing mill the fibers pass into another machine which separates the long and short fibers and at the same time throws out any stones or other refuse matter. The short fibers are ground up into pulp or powder, according to the use for which they are intended, while the longer fibers are gathered together to be woven into cloth.

It is this cloth which is used for making fireproof drop curtains for theaters. The asbestos yarn is also made into gloves and mittens for glass and iron workers and a finer cloth is woven for acid filters. To catalogue the uses of asbestos would be a long task, for within twenty years its applications have multiplied so rapidly that it now can be regarded as one of the most versatile of manufactured products. Combined with colors and oils it makes a paint which makes anything it coats either fireproof or nearly so. Asbestos combined with canvas, felt or like material, makes an excellent roofing or ceiling material, and the roofs of many factories, warehouses, docks and like structures are covered with asbestos treated material. Wood pulp or other substances which can carry the asbestos is used for covering steam pipes.

Source: The Sumpter Miner. Newspaper. March 16, 1904.